Laser cleaning

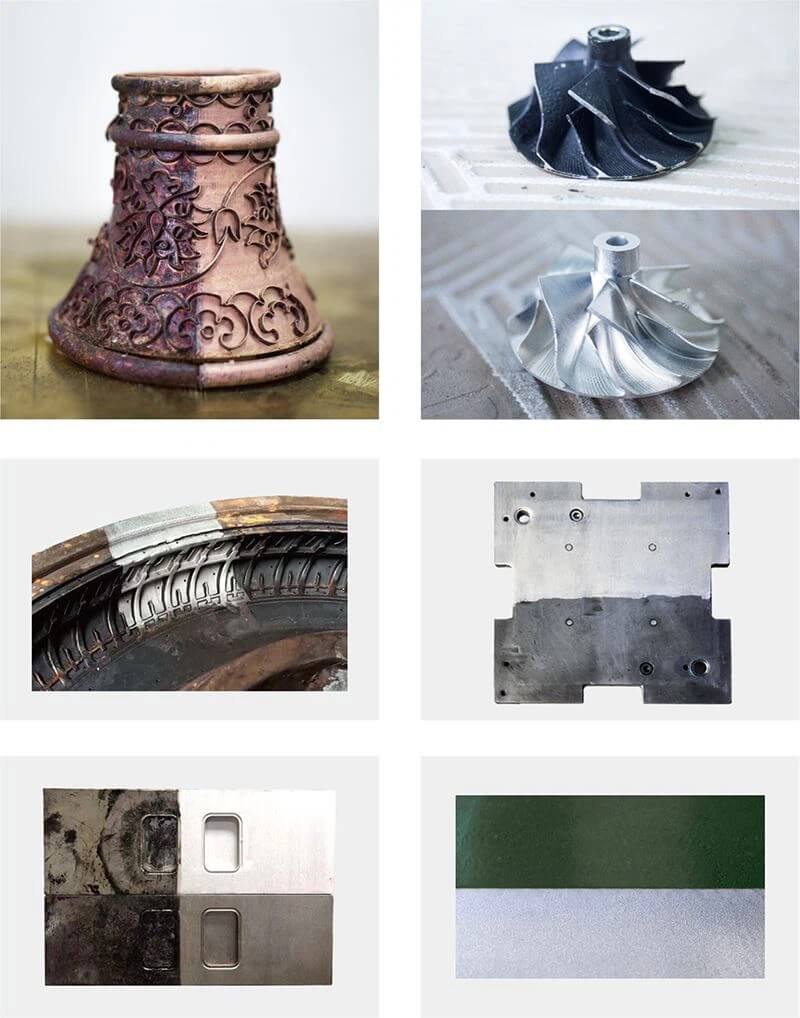

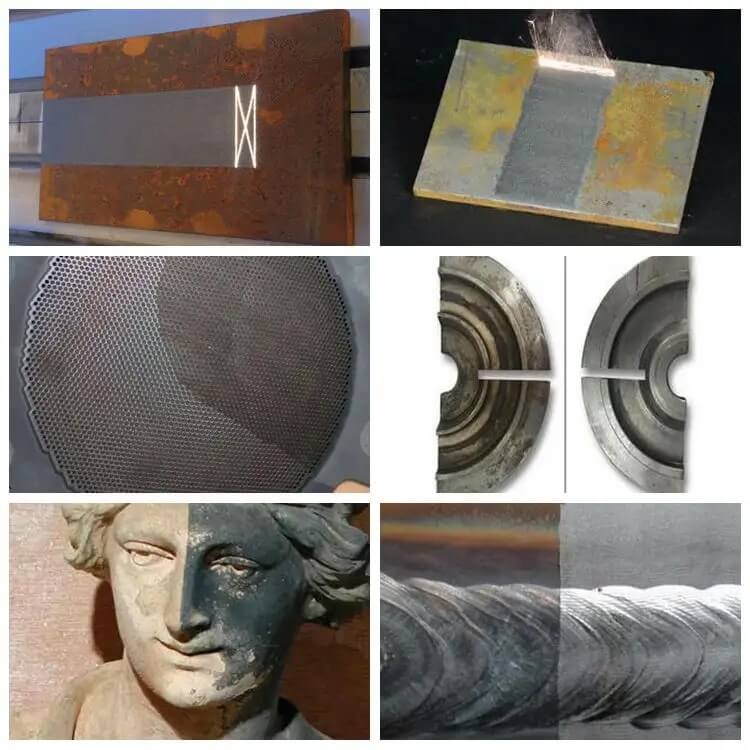

Laser ablation is an innovative and extremely safe technology used to clean a variety of, even very delicate, surfaces. The use of a precise laser beam allows for quick and non-invasive cleaning of materials such as steel, cast iron, glass, wood, or even the building’s façade from undesired tarnishes such as rust, old paint, varnish or other dirt. The laser beam is absorbed by the material being cleaned, creating a plasma, which expands and creates a shock wave that removes dirt from the material being cleaned.

Under the influence of enormous laser energy concentrated on a very small surface, the layer of material that we want to remove evaporates and goes directly from the solid state to the gaseous state, bypassing the liquid state, thanks to which the material is ready for use or further processing and does not require additional purification. Through appropriate parameter settings we can safely use it even for such delicate objects as wood or even paper.

High precision of the device allows you to control the depth and range of the removed surface.

Application

Laser ablation is widely used in virtually every field, from construction and industry to the preservation of monuments. It is an ideal solution for cleaning steel structures of bridges, railway infrastructure and even ship hulls. The laser is also extremely helpful in degreasing surfaces before painting and thoroughly cleaning them before welding or gluing.

Efficiency

Laser cleaning machine allows you to complete many hours of work in just a few minutes, with absolutely no waste as in the case of sandblasting or the use of chemicals.

Thanks to the lack of interference in the structure of the material, the obtained results significantly exceed traditional methods.